ICA Corporation

12130 Brockton Lane

Maple Grove, MN 55369

Ph: 763-428-2800

Fax: 763-428-4230

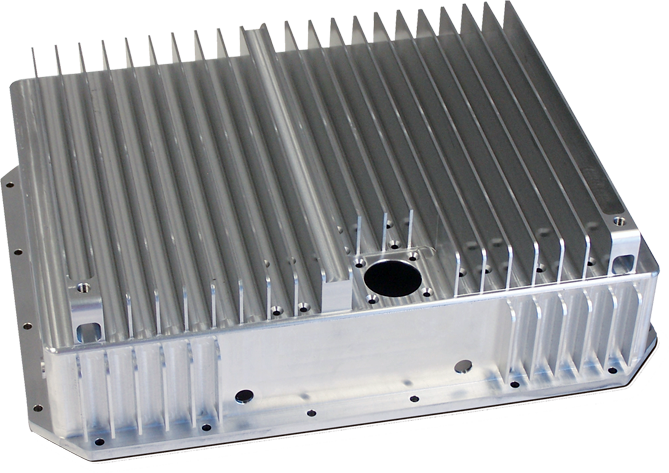

Precision Machining

- 5-axis machining – work envelope 24″ x 22″ x 20″

- Horizontal machining – work envelope 28.5″ cube

- Vertical machining – 64″ x 32″ x 26″ Z axis

- Turning to 12″ diameter x 22″ cut length, full 4th axis

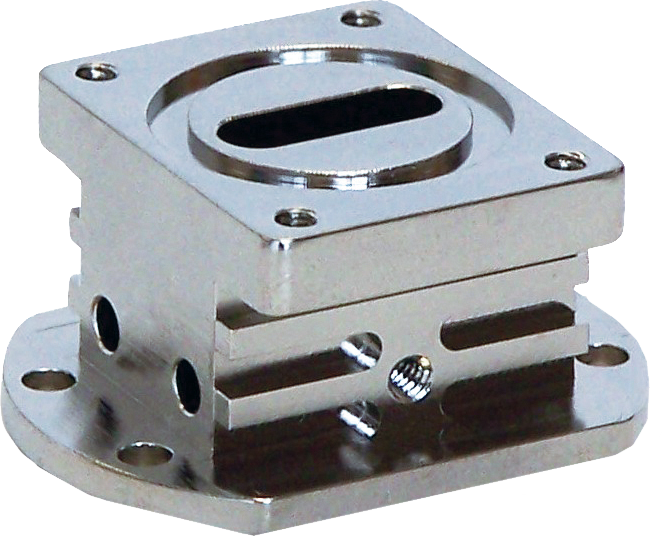

- Mechanical components for optical sub-assemblies

We work with aluminum, various stainless steels including difficult 316 and 316L, copper, most engineered plastics, titanium, molybdenum, hastelloy and other exotic materials.

Many years of experience with custom opto-mechanical components and assemblies comes from working with leading names in the optics, fiber optics, and imaging industries. We machine parts ranging from simple lens mounts, to complex flexure mounts and pointing and positioning hardware.

When designing your mechanical systems and their components, keep in mind that we can help you meet your challenges by providing design engineering support to reduce your time-to-market deadlines. We can recommend material types, tolerances, and finishes, as well as design modifications for manufacturing feasibility and flexibility. With Solid Works and Pro-E software in-house, we can import your solid models and go!

Materials:

- Stainless Steel

- Aluminum

- Delrin

- Titanium

- Nylon

- PEEK

- Molybdenum

- 316L Stainless

- Polypropylene

- Invar 36

- Copper

- Ultem

- Hastelloy

- Kovar

- Noryl

- More…

© ICA Corporation All rights reserved. Web site designed and maintained by Design-2-Part Web Design.